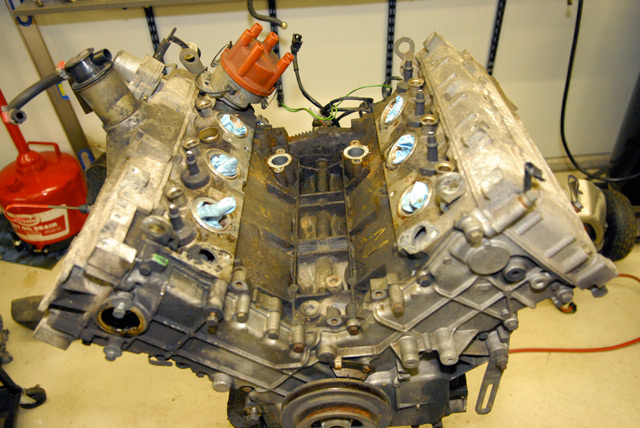

The engine ran fine, it's just filthy and has a few rotten bits. The water pump will be replaced without question. The valley will be thoroughly cleaned, then treated with POR-15.

The only way to get this engine clean is to strip it down.

Exhaust manifolds are always rusty. These were blasted, then coated with POR-15 "Factory Manifold Gray" high temperature paint. They look like freshly-blasted iron, but unlike bare iron, they'll continue to look this way after use too.

All steel pieces that were originally plated in yellow zinc have been removed (from the body too), bead-blasted down to the bare metal, then yellow zinc plated. The plating will provide an great-looking and original finish and will protect the metal for another 30 years or more.

The orignal iron brake calipers got the same treatment: fully disassemble them, glass bead blast them down to the bare metal, then re-plate in yellow zinc. These will be reassembled using all new seals and stainless steel pistons to prevent any rust issues in the future.

With stainless pistons, this caliper is now better than new!

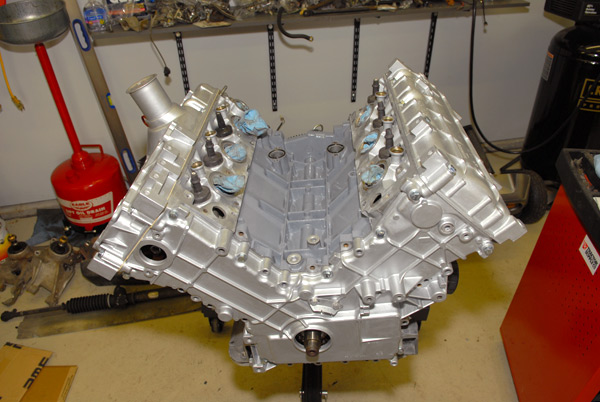

Here's the engine going back together with spruced-up covers. (Note that this photo shows painted valley plugs... that was discovered and corrected later with proper yellow zinc-plated plugs).

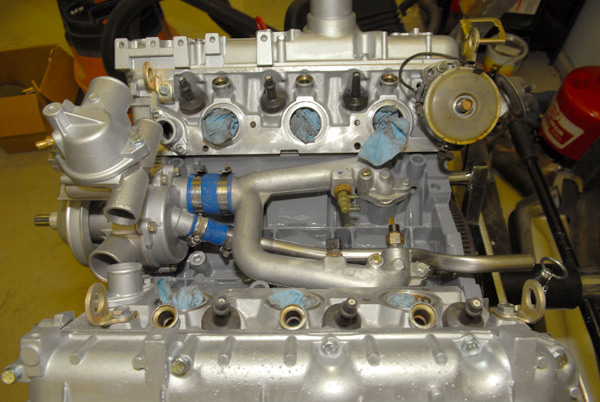

The rotten heater pipe is replaced with a stainless steel unit, combined with silicone hoses that run under the intake. The goal is to make sure that nothing will fail for a very long time.

Things are looking up from the profile view too.

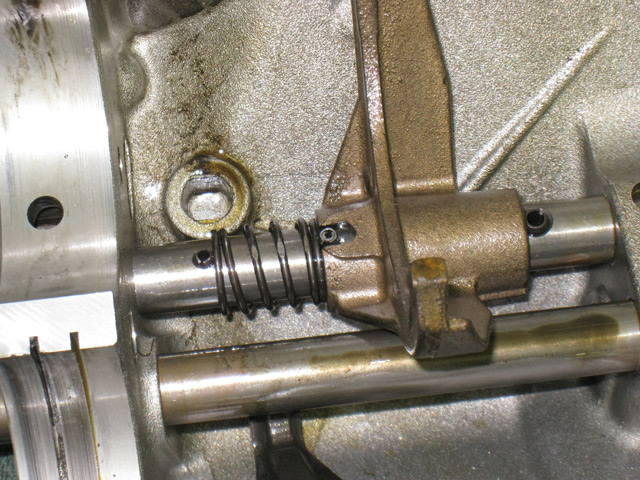

Now attention turns to the gearbox. There are two big common problems with it: the second gear roll pin sheers off and the primary shaft but has an ocasional tendency to back off and drill a hole through the end case, ruining a perfectly good transmission. Here you can see where the nut has started to back off after ~23k miles.

Here's the inside of this Renault gearbox. It's a sturdy unit aside from the roll pin.

In this case, the old roll pin was fine, but it's been replaced with a reinforced piece that will not fail.

Stainless steel sleeves are installed on the axle shafts - these will provide a tight rust-free surface for the seals, preventing oil leaks. And with this, the transmission is ready to be reassembled with fresh gaskets and anaerobic sealant down the case joints (as opposed to the factory Hylomar, which will just leak!).